Project Description

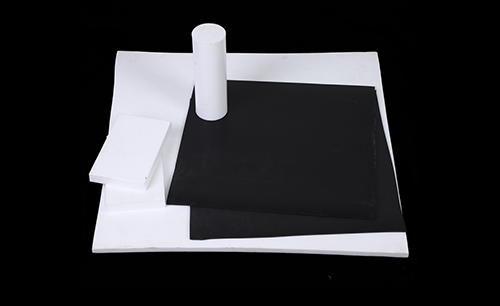

PTFE is the most chemically resistant plastic yet known, also able to remain its properties over a great temperature range.

Also, it is famous for its very low coefficient of friction. PTFE sheet is commonly used in low-cost applications, particularly used for applications where sliding action of parts is needed such as plain bearings, slide plates, insulation, etc.

Photo Gallery

Regular Specifications

- Apparent density: 2.10 – 2.30 g/cm3

- Elongation: 150 %

- Dialectic strength: 10 KV/mm

- Tensile strength: ≥15.0Mpa

- Working temperature: -180%°C – +260°C (practically)

- Molded or extrude: molded sheets & skived sheets

Regular Size for Molded PTFE Sheet

| Length(mm)×Width(mm) | Thickness(mm) | |

| Nominal | Tolerance | |

| 150×150 | 1.0-30 | ±0.30-±0.50 |

| 250×250 | 1.5-30 | ±0.30-±0.50 |

| 300×300 | 1.5-30 | ±0.30-±0.50 |

| 450×450 | 1.5-30 | ±0.30-±0.50 |

| 600×600 | 2-30 | ±0.30-±0.50 |

| 800×800 | 3-30 | ±0.30-±0.50 |

| 1000×1000 | 3-30 | ±0.30-±0.50 |

| 1200×1200 | 3-30 | ±0.30-±0.50 |

| 1000×2000 | 5-35 | ±0.30-±0.60 |

| 1500×1500 | 5-30 | ±0.30-±0.50 |

| 1800×1800 | 8-30 | ±0.30-±0.50 |

| 2000×2000 | 8-30 | ±0.30-±0.50 |

Regular Size for Skived PTFE Sheet

| Length(mm)×Width(mm) | Thickness(mm) | |

| Nominal | Tolerance | |

| 150×150 | 1.0~100 | ±0.30~±0.50 |

| 250×250 | 1.5~100 | ±0.30~±0.50 |

| 300×300 | 1.5~100 | ±0.30~±0.50 |

| 450×450 | 1.5~100 | ±0.30~±0.50 |

| 600×600 | 2~100 | ±0.30~±0.50 |

| 800×800 | 2~100 | ±0.30~±0.50 |

| 1000×1000 | 3~100 | ±0.30~±0.50 |

| 1200×1200 | 3~100 | ±0.30~±0.50 |

| 1500×1500 | 5~100 | ±0.50~±0.80 |

| 1600×1600 | 5~100 | ±0.50~±0.80 |

| 2000×1000 | 5~60 | ±0.60~±1.0 |

| 1800×1800 | 5~60 | ±0.60~±1.0 |

Packing Details

Packed with plastic film and with PP woven bag or according to your needs.