Project Description

PTFE gaskets have excellent chemical resistance and are capable of operating at high and low temperatures. They also provide good thermal stability and have good electrical properties.

Yodarubber develops wide range of PTFE gaskets including pure PTFE gasket,expanded PTFE gasket, filled PTFE gasket and PTFE spiral wound gasket.

We have been listed supplier to China’s biggest oil fields as well as the air compressor manufacturers. We also maintain a stable cooperation with transportation industry.

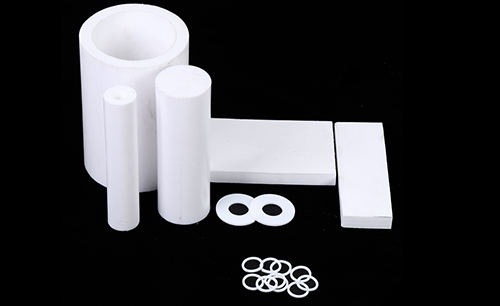

Photo Gallery

Pure PTFE Gasket

Manufactured by molding method with PTFE granular resin. Compared with other plastics, pure PTFE gasket has a superior properties against chemicals and temperature.

- Tensile Strength: 15 Mpa

- Ultimate Elongation: 125-250%

- Apparent density: 2.10-2.30 g/cm3

- Size: customized

Expanded PTFE Gasket

Cut from expanded PTFE sheet. Various size is available

- Temperature Range: up to 260 °C

- Tensile Strength: 14 Mpa

- Compressibility: 12%

- Sealing Capability: 0.1ml/hr

- Size: customized

Filled PTFE Gasket

Manufactured by molding method with filled PTFE resin.

Different fillings determines different performance, as is listed below:

| Filled compound and Content by wt | Tensile strength MPa(min) | Ultimate strength %(min) | Compressive strength MPa(min) |

| 20% glass fiber | 10 | 120 | 16 |

| 25% glass fiber | 10 | 100 | 16 |

| 20% glass fiber 5% graphite | 10 | 120 | 16 |

| 60% Bronze | 10 | 80 | 20 |

| 15% carbon fiber | 11 | 130 | 16 |

| 24% Bronze 12% glass fiber 6% graphite | 9 | 100 | 16 |

| 15% glass fiber 10% polyimide 5% graphite | 10 | 120 | 16.7 |

PTFE Spiral Wound Gasket

By winding metal with PTFE gasket. It could fix the outer ring or inner ring. PTFE spiral wound gasket is corrosion resistant as well as high pressure resistant.

Packing Details

Plastic bags in inner and outer carton or other packing method based on your requirements.