Project Description

EPDM rubber sheet is highly versatile with a variety of applications.

It is particularly popular in automotive industry, as a much less costly alternative to silicone and can last for long periods of time with proper use. However, food application is not recommended.

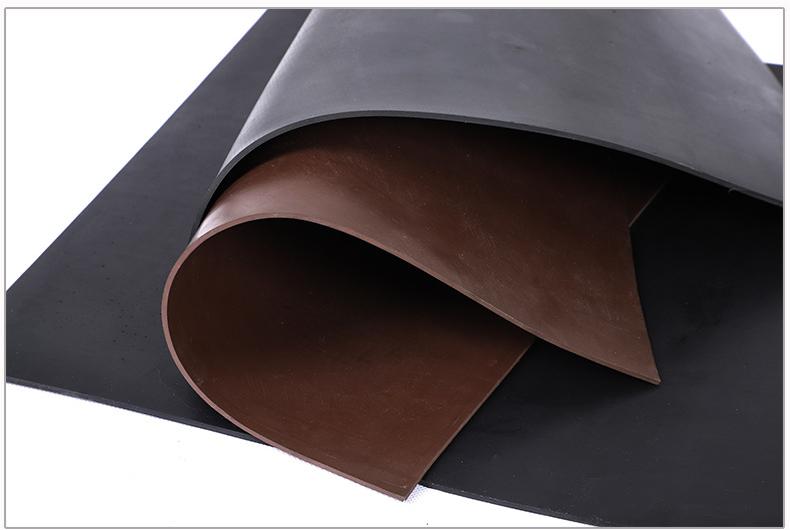

Photo Gallery

Specifications & Available Size

| Durometer | Thickness (in.) | Width (in.) | Tensile Strength Psi | Ultimate Elongation Percent | Temperature Range | Weight | Specifications |

|---|---|---|---|---|---|---|---|

| 40 | 1/64 - 1/4 | 36, 48 | 800 | 300 | -40°F to +212°F | 7.2 | ASTM D 2000 SAE J200 3BA 408 C12 MIL R-3065 RS 408 C12 |

| 50 | 1/64 - 1/4 | 36, 48 | 800 | 300 | -40°F to +212°F | 7.5 | ASTM D 2000 SAE J200 3BA 508 C12 MIL R-3065 RS 508 C13 |

| 60 | 1/64 - 1/4 | 36, 48 | 800 | 250 | -40°F to +212°F | 7.8 | ASTM D 2000 SAE J200 3BA 608 C12 MIL R-3065 RS 608 C14 |

| 70 | 1/64 - 1/4 | 36, 48 | 800 | 150 | -40°F to +212°F | 8.1 | ASTM D 2000 SAE J200 3BA 708 C12 MIL R-3065 RS 708 C15 |

| Durometer | Thickness (in.) | Width (in.) | Tensile Strength Psi | Ultimate Elongation Percent | Temperature Range | Weight | Specifications |

|---|---|---|---|---|---|---|---|

| 40 | 1/64 - 1/4 | 36, 48 | 1100 | 400 | -50°F to +225°F | 6.1 | ASTM D 2000 5BA 410 C12 F17 |

| 50 | 1/64 - 1/4 | 36, 48 | 1200 | 350 | -50°F to +225°F | 6.6 | ASTM D 2000 5BA 510 C12 F17 |

| 60 | 1/64 - 1/4 | 36, 48 | 1300 | 350 | -50°F to +225°F | 6.7 | ASTM D 2000 5BA 610 C12 F17 |

| 70 | 1/64 - 1/4 | 36, 48 | 1400 | 250 | -50°F to +225°F | 6.85 | ASTM D 2000 5BA 710 C12 F17 |

| 80 | 1/64 - 1/4 | 36, 48 | 1500 | 200 | -50°F to +225°F | ASTM D 2000 5BA 815 C12 F17 |

| Durometer | Thickness (in.) | Width (in.) | Tensile Strength Psi | Ultimate Elongation Percent | Temperature Range | Weight | Specifications |

|---|---|---|---|---|---|---|---|

| 40 | 1/64 - 1/4 | 36, 48 | 1550 | 550 | -55°F to +300°F | 6.4 | ASTM D 2000 4CA 415 A25 B35 C32 EA14 F19 |

| 50 | 1/64 - 1/4 | 36, 48 | 1600 | 400 | -55°F to +300°F | 6.3 | ASTM D 2000 4CA 515 A25 B35 C32 EA14 F20 |

| 60 | 1/64 - 1/4 | 36, 48 | 1800 | 350 | -55°F to +300°F | 6.45 | ASTM D 2000 4CA 615 A25 B35 C32 EA14 F21 |

| 70 | 1/64 - 1/4 | 36, 48 | 1700 | 250 | -55°F to +300°F | 6.6 | ASTM D 2000 4CA 715 A25 B35 C32 EA14 F22 |

| 80 | 1/64 - 1/4 | 36, 48 | 1800 | 200 | -55°F to +300°F | ASTM D 2000 4CA 815 A25 B35 C32 EA14 F23 |

| Item | Width (mm) | Thickness (mm) | Length |

|---|---|---|---|

| Yoda 001 | 1000 | 1 | Customized |

| Yoda 002 | 2 | ||

| Yoda 003 | 3 | ||

| Yoda 004 | 4 | ||

| Yoda 005 | 5 | ||

| Yoda 006 | 6 | ||

| Yoda 007 | 7 | ||

| Yoda 008 | 8 | ||

| Yoda 009 | 9 | ||

| Yoda 010 | ≥ 10 | ||

| Yoda 011 | 1000-1200 | 1.5 | |

| Yoda 012 | 2 | ||

| Yoda 013 | 3 | ||

| Yoda 014 | 4 | ||

| Yoda 015 | 5 | ||

| Yoda 016 | 6 | ||

| Yoda 017 | 7 | ||

| Yoda 018 | 8 | ||

| Yoda 019 | 9 | ||

| Yoda 020 | ≥ 10 | ||

| Yoda 021 | 1200-1500 | 1.5 | |

| Yoda 022 | 2 | ||

| Yoda 023 | 3 | ||

| Yoda 024 | 4 | ||

| Yoda 025 | 5 | ||

| Yoda 026 | 6 | ||

| Yoda 027 | 7 | ||

| Yoda 028 | 8 | ||

| Yoda 029 | 9 | ||

| Yoda 030 | ≥ 10 |